Imveliso

Umsebenzi opheleleyo we-granulation kunye nokusebenza kakuhle kwemveliso

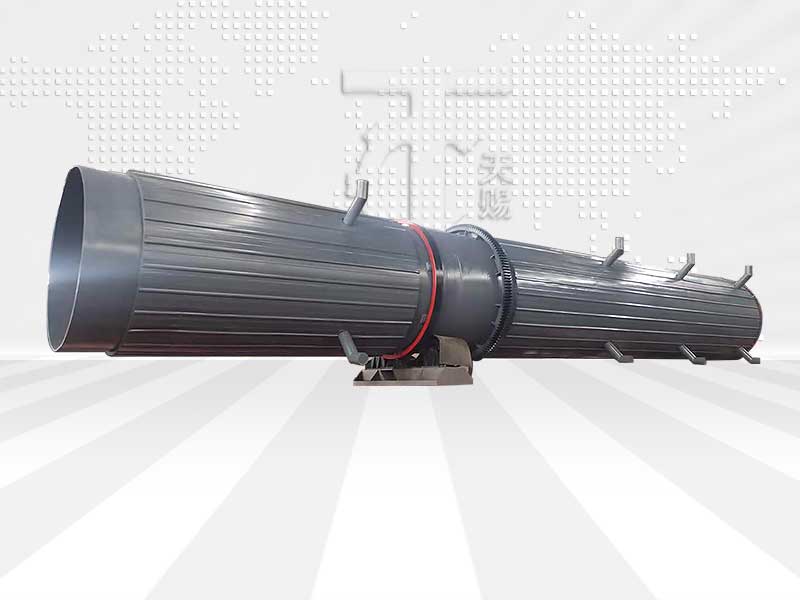

Idramu yesichumisi seSichumisi

Intshayelelo yeMveliso

Isichumisi sesichumiso se-Rotary sisetyenziselwa ukomisa isichumisi se-granular eziphilayo kunye nesichumisi se-granular compound.Ngenxa yeempawu zokuba umthamo wamanzi wamasuntswana e-organic fertilizer okanye isichumiso esihlanganisiweyo / amasuntswana e-compounds fertilizer ayikho ngaphezu kwe-35%, kwaye ukuqina kwamasuntswana esichumiso kuncinci kunoko kwe-slime yamalahle, ipleyiti yokuphakamisa kunye nebhere yesi somisi zincinci. ilungiselelwe ukunqanda ukutshabalalisa imilo yamasuntswana ochumiso.

Iimpawu zoMsebenzi

UmGaqo wokuSebenza

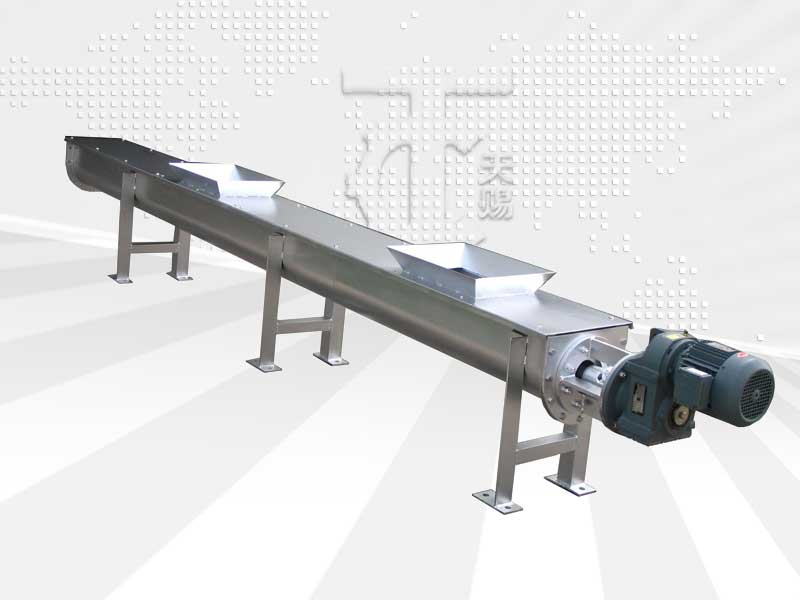

Isichumisi sesichumiso se-Rotary sisetyenziselwa ukomisa isichumisi se-granular eziphilayo kunye nesichumisi se-granular compound.Amasuntswana ezichumisi athuthwa asiwe kwizibuko lesondlo lesomisi sochumisi ngomthuthi.Amasuntswana ezichumisi angena kwizibuko lokutya kwesomisi, kwaye umthombo wobushushu owomileyo ungeniswa kumthombo wobushushu ngokusebenzisa idrafti yedrafti yedrafti evela kwizibuko elisezantsi.Ngaloo ndlela, izinto eziwela kwi-port feed kwaye zihamba ukusuka ezantsi ukuya phezulu kunye nomoya oshushu ukwenza uqhagamshelwano oluphambene phakathi kwesichumisi kunye nomthombo wokushisa, kwaye emva koko uqhubela kwi-port yokukhupha i-dryer ngezantya ezahlukeneyo.Ngaphantsi kwesenzo sepleyiti yokuphakamisa, iinqununu zesichumisi ziqhubeka ziphakamisa kwaye ziwa, ukwenzela ukuba isichumisi kunye nomthombo wokushisa udityaniswe ngokupheleleyo, Qonda ukukhuphuka kwamanzi ngokukhawuleza ukuhlangabezana neemfuno zomxholo wamanzi ojoliswe kuyo.

Iiparamitha zesichumisi seGubu

| Umzekelo | Ububanzi (mm) | Ubude (mm) | Dip engile (°) | Isantya (r/min) | Ugqithiso (t/h) | amandla (kw) |

| ZG12×6 | 1200 | 6000 | 3 | 5 | 0.5-1 | 5.5 |

| ZG14×7 | 1400 | 7000 | 3 | 5 | 2-3 | 7.5 |

| ZG16×8 | 1600 | 8000 | 3 | 5 | 3-5 | 11 |

| ZG18×9 | 1800 | 9000 | 3 | 4 | 4-6 | 15 |

| ZG20×10 | 2000 | 10000 | 3 | 4 | 6-8 | 18.5 |

Cela iQuote

Khetha imodeli kwaye ubeke iiodolo

Khetha imodeli kwaye ungenise injongo yokuthenga

Fumana ixabiso elisisiseko

Abavelisi bathatha inyathelo lokuqala lokuqhagamshelana nokwazisa i-lo

Ukuhlolwa kwezityalo

Isikhokelo soqeqesho lweengcali, utyelelo lokubuyela rhoqo

Sayina isivumelwano

Khetha imodeli kwaye ungenise injongo yokuthenga

Fumana olona nikezelo luncinci simahla , nceda ugcwalise olu lwazi lulandelayo ukuze usixelele ( ulwazi oluyimfihlo , olungavulelwanga kuluntu )

Ityala leProjekthi

Funda ngakumbi Sijoyine

Iimveliso ze-carbide ezisemgangathweni zine-inventory enkulu, iimveliso ezilungiselelwe zinokuveliswa ngokutsha kunye nokubumba kugqityiwe.

Fumana ikowuteshini

Fumana ikowuteshini +8613203835178

+8613203835178