Imveliso

Umsebenzi opheleleyo we-granulation kunye nokusebenza kakuhle kwemveliso

Isikrufu sokuhambisa isichumiso/ikhemikhali/ishishini kunye nesinyithi

Ingcaciso yeMveliso

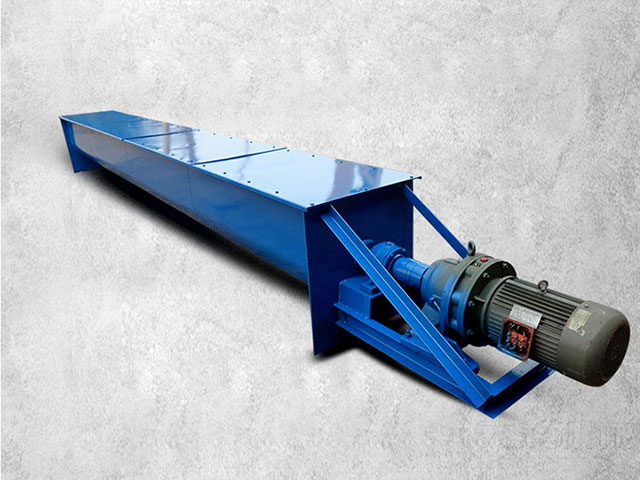

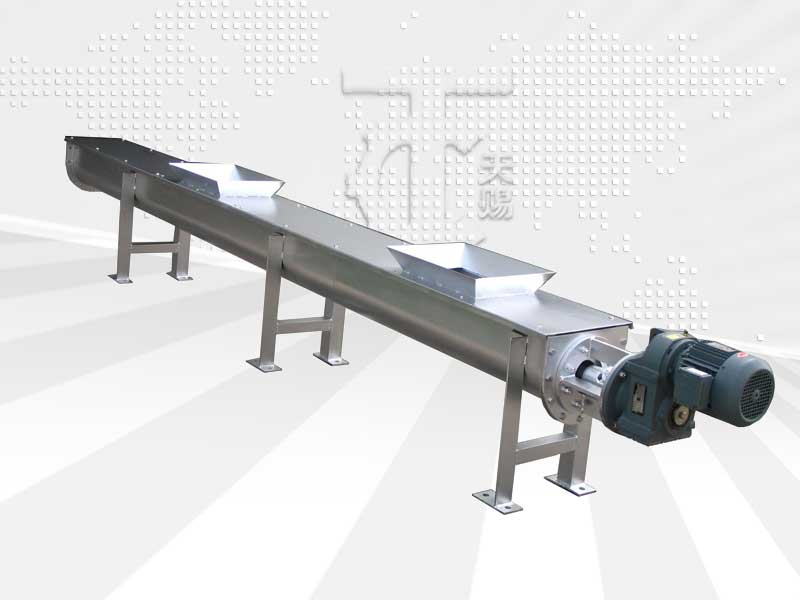

I-screw conveyor ithatha umbhobho wentsimbi ohambisa isilinda, enobungqongqo obuphezulu, ukusebenza kakuhle kokutywina, akukho kuvuza, kunye nokuphucula indawo yokusebenza.

Isixhobo sokuhambisa samkela i-motor edityaniswe ngokuthe ngqo i-cycloidal pinwheel reducer, enamandla amakhulu, ingxolo ephantsi, isakhiwo esincinci kunye nokuhanjiswa okuthembekileyo.Umatshini wonke unokufakwa ngokuthe tye okanye oblique, kunye neenyawo ezincinci, ukufakwa lula kunye nokusetyenziswa okulula.

Umatshini unokwahlulwa ube ngamacandelo amathathu

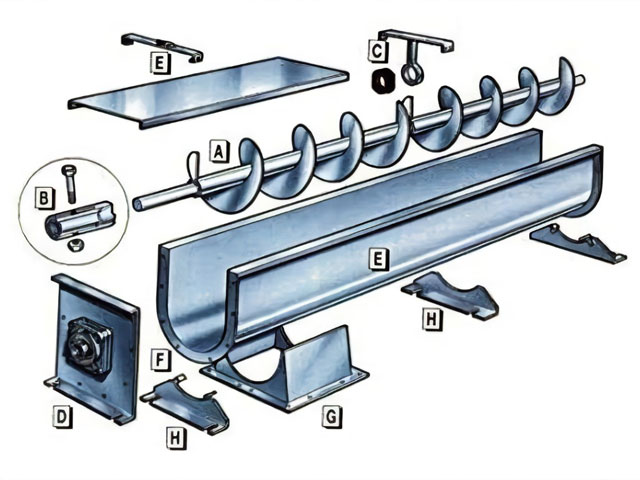

1. I-screw conveyor luhlobo olungelulo olusisiseko.Iqulunqwe isixhobo esisisixhobo esilungiselelweyo kunye netyhubhu ye-casing, kwaye i-screw assembly idityaniswe omnye komnye ngokulandelelana, kwaye idityaniswe kwiseti epheleleyo yezixhobo, ekulungele kakhulu ukuhambisa, ukuqhawula kunye nokudibanisa.

2. Indibano ye-screw kunye ne-shaft end idibaniswe yi-splines, ekulula ukuyihlanganisa kunye nokuchithwa, inomthamo omkhulu wokuthwala, ukungathathi hlangothi okulungileyo, kwaye ikhuselekile kwaye inokwethenjelwa.

3. Umsebenzi wokutywina ulungile, igobolondo lenziwe ngombhobho wensimbi ongenamthungo, kwaye isiphelo ngasinye sidityaniswe ngamaflange, umatshini wonke awunakuvuza uthuli, kwaye akukho nkunkuma yezinto eziphathekayo, ukwenzela ukudala indawo efanelekileyo yokusebenza kunye nokuhlangabezana nokukhuselwa kwendalo. iimfuno.

4. Ubungakanani obuncinci, isantya esiphezulu, i-pitch eguquguqukayo, ukuqinisekisa ukukhawuleza kunye nokuhanjiswa.

5. I-port feeding ingenziwa kwi-angle inclination efunekayo ngokwemiqathango yesayithi yokusebenza, kwaye inokudibaniswa ne-flange, i-bag connection kunye ne-universal joint flange, enokukhethwa ngabasebenzisi ngokweemfuno zabo.

Iiparamitha zobuGcisa

| Umzekelo | Idayamitha ye-Spiral (mm) | Isantya sokujikeleza (r/min) | Ukuhanjiswa komthamo osemgangathweni (m3/h) |

| LS160 | 160 | 112 | 9.7-3.2 |

| 90 | 7.8-2.6 | ||

| 71 | 6.2-2.1 | ||

| 56** | 4.9-1.6 | ||

| LS200 | 200 | 100 | 16.9-5.6 |

| 80 | 13.5-4.5 | ||

| 63 | 10.7-3.6 | ||

| 50** | 8.5-2.8 | ||

| LS250 | 250 | 90 | 29.9-9.9 |

| 71 | 23.5-7.8 | ||

| 56** | 18.5-6.2 | ||

| 45** | 14.9-5.0 | ||

| I-LS315 | 315 | 80 | 52.9-17.6 |

| 63 | 41.6-13.9 | ||

| 50** | 33.1-11.0 | ||

| 40** | 26.4-8.8 | ||

| LS400 | 400 | 71 | 85.3-28.2 |

| 56 | 67.3-22.4 | ||

| 45** | 54.1-18 | ||

| 36** | 43.2-14.4 |

Cela iQuote

Khetha imodeli kwaye ubeke iiodolo

Khetha imodeli kwaye ungenise injongo yokuthenga

Fumana ixabiso elisisiseko

Abavelisi bathatha inyathelo lokuqala lokuqhagamshelana nokwazisa i-lo

Ukuhlolwa kwezityalo

Isikhokelo soqeqesho lweengcali, utyelelo lokubuyela rhoqo

Sayina isivumelwano

Khetha imodeli kwaye ungenise injongo yokuthenga

Fumana olona nikezelo luncinci simahla , nceda ugcwalise olu lwazi lulandelayo ukuze usixelele ( ulwazi oluyimfihlo , olungavulelwanga kuluntu )

Ityala leProjekthi

Funda ngakumbi Sijoyine

Iimveliso ze-carbide ezisemgangathweni zine-inventory enkulu, iimveliso ezilungiselelwe zinokuveliswa ngokutsha kunye nokubumba kugqityiwe.

Fumana ikowuteshini

Fumana ikowuteshini +8613203835178

+8613203835178